FOR LIP SEALS WITH SEAL REVITALISER

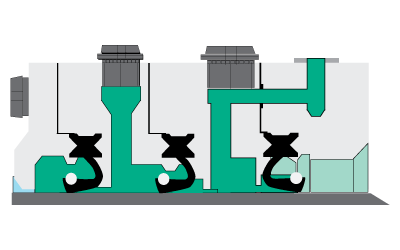

An effective additive for Stern Tubes, Bow Thrusters, Azimuth Thrusters and CPPs.

MPS 896 Special Mix is usually used in systems with water ingress, when there is an access to the sealing chambers from the aft seal tank.

Description

Dynamic barrier in aft seal chambers

In addition to high concentration of PTFE, MPS 896 Special Mix contains another additive, which gives the paste different structure and makes it cling to the rotating shaft with a firm grip.

The „firm grip“ on the shaft ensures that the higher level of PTFE is interlocked right in front of any given slip between the seal and the shaft, offering a tougher sealing effect that will withstand greater forces from the sea.

The paste’s seal revitalizing additive preserves or restores flexibility of the rubber seals without swelling.

BENEFITS

- Lubrication with solids

MPS contains a high concentration of PTFE and Bentonite - No water/oil emulsion

MPS does not emulsify with oil or water - Compatible with most oil types

Oil is used as a carrier for solid particles, PTFE and Bentonite - Broad working temperature range

MPS tolerates temperatures from -30° C to 260° C - MPS contains seal revitalizing additive

Compatible with FKM and NBR elastomers

MPS restores seals elasticity without swelling - Surface treatment

MPS polishes the surface and fills in cracks of up to 2 mm

MPS provides static lubrication due to surface fluorination - Anti-corrosion and EP properties

MPS enhances corrosion protection and allows increased loads

HOW TO APPLY MPS 896 SPECIAL MIX

The MPS 896 Special Mix paste must be injected in its concentrated form directly to the aft seal chambers.

Important: It is necessary to have a suitable pump for the application. Lindemann can supply a high-pressure pump, which suits the 20 kg drum, for easy application. The pump can later be used for other purposes.

TYPICAL APPLICATION AREAS

COMPATIBILITY

- MPS 896 Special Mix will work equally well with most materials e.g. bronze, chrome, stainless steel or brass and rubber, asbestos and plastics

- MPS 896 Special Mix is compatible with NBR and FKM elastomers

- MPS 896 Special Mix can be used as an additive with both mineral oil and EALs

TREATMENT RATE

Apply 100% of MP 896 Special Mix to aft seal chambers only.

Please, consult Lindemann team for application instructions and the necessary quantity.